Stamping Pressing Punching Car Auto Vehicle Parts Accessories Fitting Mountings Sx276

Model NO.: SX276

Size: D15*87mm

Lifting Capacity: 2t

Update Method: via Internet

Surface Treatment: Nickel Plating

Trademark: SX

Transport Package: 16PCS/PE Bag/ Carton

Specification: D15*87MM

Origin: Dongguan, China

This high-quality CNC-machined steel adapter spade kit is designed to help you attach your alignment heads to small edge rims that are hard to fit, while protecting the surface of your expensive wheels from scratches. The set includes 16 pieces and is compatible with all four wheel clamps or adaptors. These adapters easily snap onto modern rounded clamp studs or feet, making installation quick and efficient. Key Benefits: - Prevents scratches and damage to costly rims - Makes it easier to mount small-lip rims - A cost-effective alternative to buying new wheel adapters - Simple to use – just snap onto existing feet - Works with slide-type, screw-type, and self-centering wheel clamps Dongguan Shengxin Metal Manufacturing Co., Ltd. specializes in the design, manufacturing, and sale of auto maintenance machine parts. With a management philosophy centered on "high quality, honesty, cooperation, innovation, and continuous improvement," we focus on enhancing technology and production efficiency. We started our journey in metal stamping, deep drawing, and precision machining, including chassis stamping, machine stamping, and car parts stamping. Since 2007, we have expanded into the professional auto maintenance parts industry, offering a wide range of products such as wheel alignment clamps, aligner adaptors, turntables, steering wheel holders, brake disc supports, and more. We are proud to be leaders in our field, continuously creating our own brand and product patents. We have already obtained a patent for the clamp set stud. Our commitment to product design, quality, and production efficiency has placed us at the forefront of the industry. Our Advantages: - Professional stamping mold making - Reliable quality - Competitive pricing - Excellent customer service - Timely delivery - Outstanding after-sales support Our Vision: Starting from Shenzhen and Dongguan, we aim to expand globally. We are your best partner for high-quality products that help you achieve maximum business value.

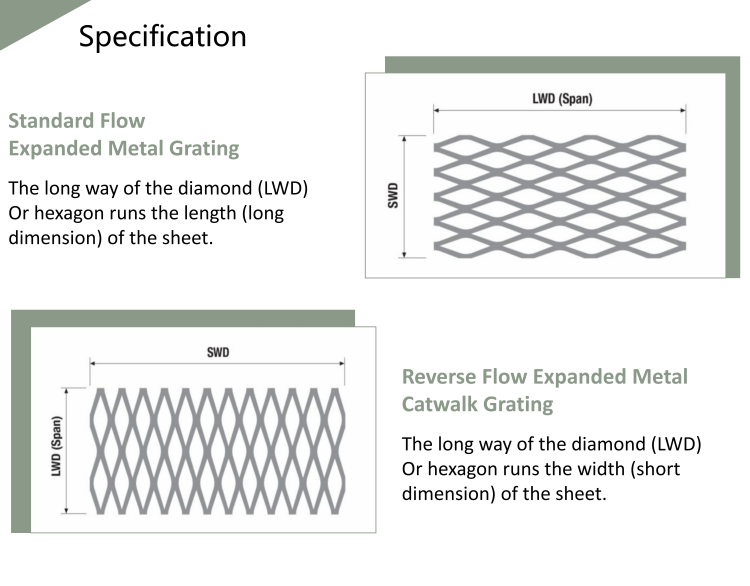

Aluminum perforated metal is a type of metal plate with perforated design, commonly used in architectural decoration, acoustic treatment, and industrial applications. Its characteristics and uses are as follows:

Characteristics:

1. Aesthetics: Perforation design can provide a unique visual effect, increasing the aesthetic appeal of buildings or products.

2. Ventilation: The design of the holes allows for air circulation and is suitable for applications that require good ventilation.

3. Acoustic performance: In some cases, perforated metal can improve the propagation characteristics of sound, absorb noise or reflect sound.

4. Lightweight: Due to the material being removed to form holes, the overall weight is relatively light.

5. Durability: Aluminum material itself has good corrosion resistance and durability.

Application areas:

-Architectural Decoration: Indoor and outdoor walls, ceilings, partitions, etc.

-Acoustic Processing: Spaces such as recording studios, concert halls, and offices that require controlled sound environments.

-Filters and Screens: Filter materials used in industrial filtration equipment.

-Furniture manufacturing: Decorative elements for furniture such as lamps, chairs, tables, etc.

-Billboards and signage: Used for creating creative outdoor advertising display boards.

Processing method:

Aluminum perforated metal can be manufactured through various methods, including stamping, laser cutting, waterjet cutting, and other technologies. Different processing methods can affect the cost, accuracy, and applicability of the final product.

When choosing aluminum perforated metal, factors such as hole size, hole spacing, and plate thickness should be considered according to specific application scenarios to ensure that specific requirements are met.

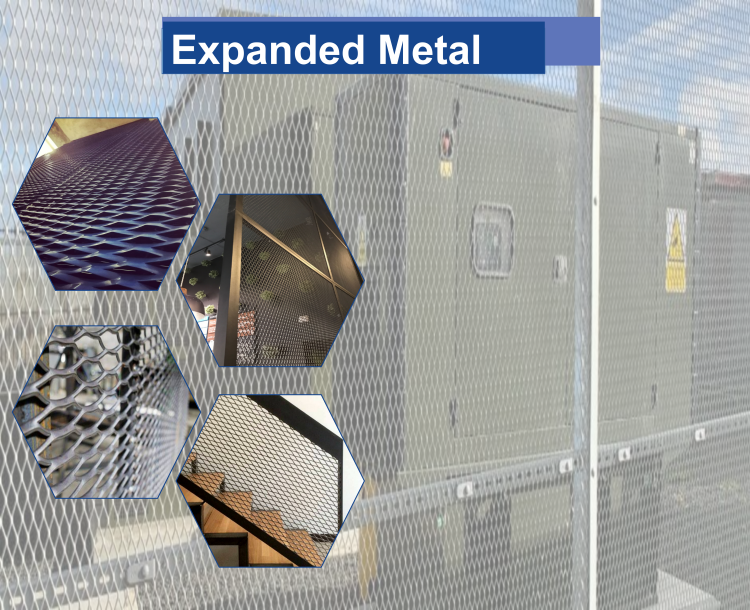

Aluminum Perforated Metal,Expended Metal Mesh Aluminum Grid Fence,Aluminum Expended Plate Wire Mesh,Aluminum Diamond Hole Expended Mesh Plate Screen

Hebei Yingkang Wire Mesh Product Co.Ltd , https://www.wiremesh-china.com