Molds have completely transformed the manufacturing landscape, enabling suppliers to efficiently produce identical parts in quick succession. Among the various molding processes, injection molding stands out as a popular method, where molten plastic is injected into a mold to form a component. This technique is extensively utilized across industries such as automotive, aerospace, industrial, and medical sectors. Injection molding can be further categorized into two main types: insert molding and overmolding.

---

### **What is Insert Molding?**

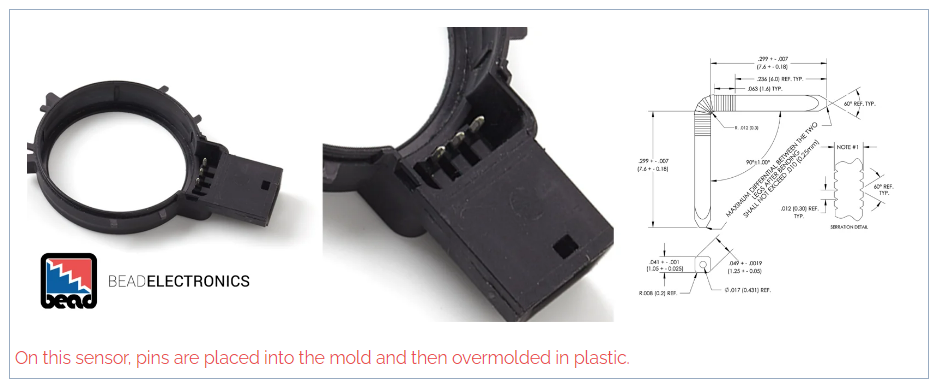

Insert molding involves placing pre-formed components into a mold before injecting molten plastic, resulting in a single integrated component. A common example includes threading inserts into fasteners or embedding metal contact pins into connectors.

This approach significantly cuts down on the cost of individual parts, eliminates the need for manual assembly, and maximizes overall savings. Additionally, it combines the lightweight benefits of plastic with the robustness of metal, leading to more durable products. However, if the components are custom-made rather than standard off-the-shelf parts, this can introduce extra time and cost into the production process.

#### **When to Use Insert Molding**

Consider using insert molding when your part requires:

- A metal component.

- Threaded inserts.

- Embedded sub-assemblies like wires, electronic parts, or circuit boards.

#### **How to Implement Insert Molding**

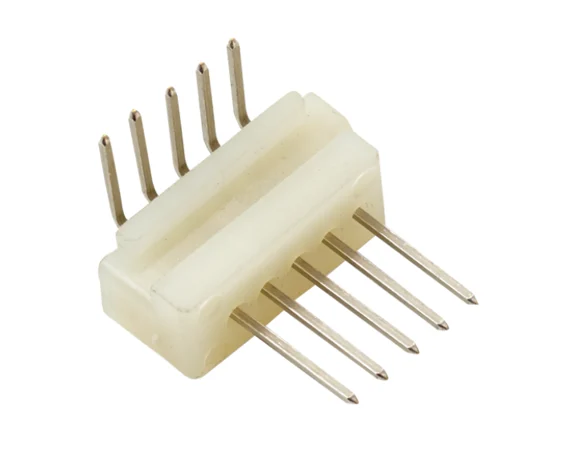

Insert molding opens up creative possibilities. For instance, mass-producing sub-assemblies like Right Angle Pin Headers simplifies placement within the mold, reducing the need for manual intervention. This streamlined process saves both time and resources.

To proceed effectively, ensure your design files are complete and accessible to engineers or designers. Your final design should include CAD models to assess how the inserts impact the structure. Document any necessary Design for Manufacturing (DFM) considerations to evaluate product quality before fabrication.

---

### **What is Overmolding?**

Overmolding is a specialized form of insert molding where one molded part is encapsulated by another layer of plastic. First, the initial component is produced in a mold, which is then placed into a secondary mold for the final product. This method is frequently seen in handles, where a softer plastic is overlaid onto a firmer base to enhance grip comfort.

By merging multiple materials into one component, overmolding reduces assembly costs and eliminates the need for adhesives or bonding agents. It creates more versatile products with varied textures, colors, or functional properties. For instance, embedding soft seals into products is a common application.

#### **When to Use Overmolding**

Opt for overmolding when your application demands:

- Different thermal or electrical properties.

- Shock absorption or vibration dampening.

- Multi-colored designs.

- Comfortable, non-slip grips.

- Embedded soft seals.

Overmolded parts can also be further customized based on specific requirements. These components are particularly well-suited for the automotive industry, where contact pins can be overmolded with plastic or rubber for use in vehicle sensors, control units, or infotainment systems.

---

### **Choosing Between Insert Molding and Overmolding**

While insert molding tends to be more cost-effective and quicker, overmolding might prove advantageous if your component requires complex integration. Deciding between the two depends entirely on your project’s unique specifications.

At Bead Electronics, we’ve been a trusted partner in supplying pins for insert-molded and overmolded connectors across industries like automotive, telecommunications, aerospace, industrial, and medical fields. Our contact pins are versatile, suitable for power, signal, or electromechanical applications.

Have questions? Reach out to our specialists today! We’re here to help guide you through the best solution for your needs.

Stage Collar

Stage Collar,Drilling Equipment Collar,Cement Head Accessories,Oilfield Equipment Components

Puyang Zhongshi Group Co.,Ltd , https://www.puyangzhongshi.com