Molds have completely transformed the manufacturing landscape, allowing suppliers to efficiently produce identical parts in quick succession. Among the most popular molding techniques is injection molding, which involves injecting molten plastic into a mold to form a component. This method is extensively used across industries like automotive, aerospace, industrial equipment, and healthcare. Injection molding can be further categorized into two main types: insert molding and overmolding.

### What is Insert Molding?

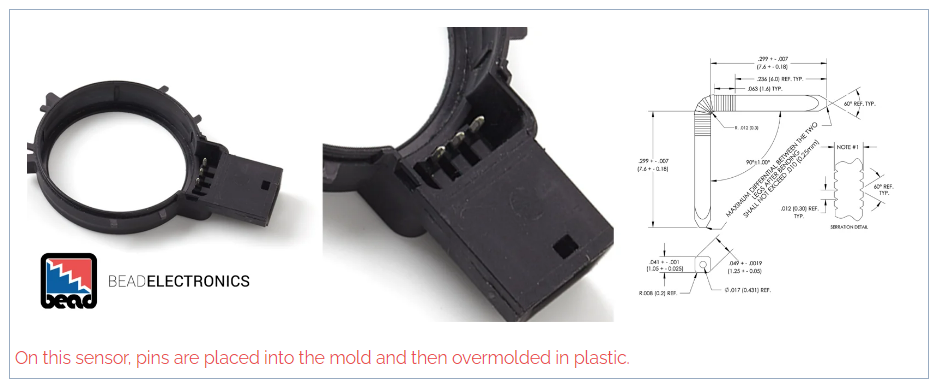

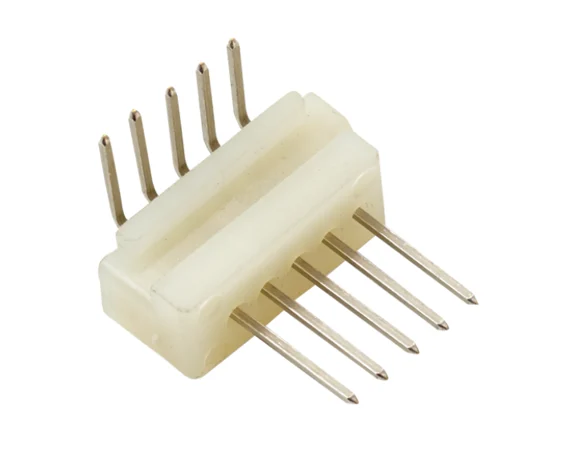

Insert molding is a manufacturing process where pre-formed components are placed within a mold before injecting the molten plastic. This creates a single, integrated part. For instance, threaded inserts are often molded directly into fasteners, while metal contact pins serve as inserts for electrical connectors.

One of the significant advantages of insert molding is its ability to reduce the cost of individual parts by eliminating the need for assembly, thereby maximizing overall savings. It also combines the lightweight benefits of plastic with the strength and rigidity of metal, leading to a more robust final product. However, if the components being inserted are custom-made rather than standard parts, this can increase both the time and cost involved in production.

#### When to Use Insert Molding

Consider using insert molding when your part requires:

- A metal component.

- Threaded inserts.

- Embedded electronics, wires, or circuit boards.

#### How to Implement Insert Molding

Insert molding offers creative opportunities by allowing components to be mass-produced as sub-assemblies. For example, right-angle pin headers can be easily loaded into the molding machine, avoiding the labor-intensive step of individually placing each pin. This results in a streamlined, one-step process that saves both time and resources.

Before proceeding, ensure all necessary design files are prepared for engineers or designers to review. The final design should include insert CAD to assess how much space the inserts will occupy. This helps understand the impact on the product’s structural integrity. Additionally, any design for manufacturability (DFM) considerations should be documented to evaluate the product’s quality prior to production.

---

### What is Overmolding?

Overmolding is a specialized form of insert molding where one molded part is encased in another layer of plastic. First, the base component is created in an injection mold, and then it is inserted into a secondary mold to form the final product. This approach is commonly seen in handles, where a softer material is molded over a firmer base to provide a more ergonomic grip.

By integrating multiple materials into a single component, overmolding cuts down on assembly costs and removes the need for adhesives or other bonding agents. The combined materials enhance the product’s functionality, offering varied textures, colors, or performance characteristics. Overmolding is particularly effective for embedding soft seals into devices.

For instance, pin assemblies can be manufactured as a single unit, eliminating the hassle of placing individual pins, thus improving precision and efficiency.

However, maintaining optimal temperatures during the process is critical. If not controlled properly, delamination might occur. Since overmolding typically requires two molds or a more intricate two-shot mold setup, it tends to be pricier than producing a single part. Despite the higher upfront costs, overmolding remains cost-effective compared to creating two separate parts and assembling them manually.

#### When to Consider Overmolding

Use overmolding when your application demands features such as:

- Different thermal or electrical properties.

- Shock absorption or vibration dampening.

- Multiple colors or textures.

- Comfortable, non-slip grips.

- Embedded soft seals.

Overmolded components can also be customized further based on specific needs. Their exceptional durability makes them ideal for the automotive sector, where they are frequently used in connectors for vehicle sensors, control units, or infotainment systems.

---

### Choosing Between Insert Molding and Overmolding

While insert molding is generally more affordable and quicker to execute, overmolding might be preferable if custom designs are required. The decision ultimately depends on the specific requirements of your component.

At Bead Electronics, we’ve been supplying pins for a wide range of insert-molded and overmolded connectors across industries such as automotive, telecommunications, aerospace, industrial machinery, and medical equipment. Our contact pins can support power, signal, or electromechanical applications within these connectors.

Feel free to reach out to our specialists to discuss your unique requirements!

---

This text has been expanded from the original content while maintaining clarity and readability, aiming for authenticity in tone and structure.

Blowout Preventer

Blowout Preventer,Bop Blowout Preventer,Wellhead Spools,Api Oilfield Bop

Puyang Zhongshi Group Co.,Ltd , https://www.puyangzhongshi.com