The Importance of Proper Robot Operator Training

The Importance of Proper Robot Operator Training

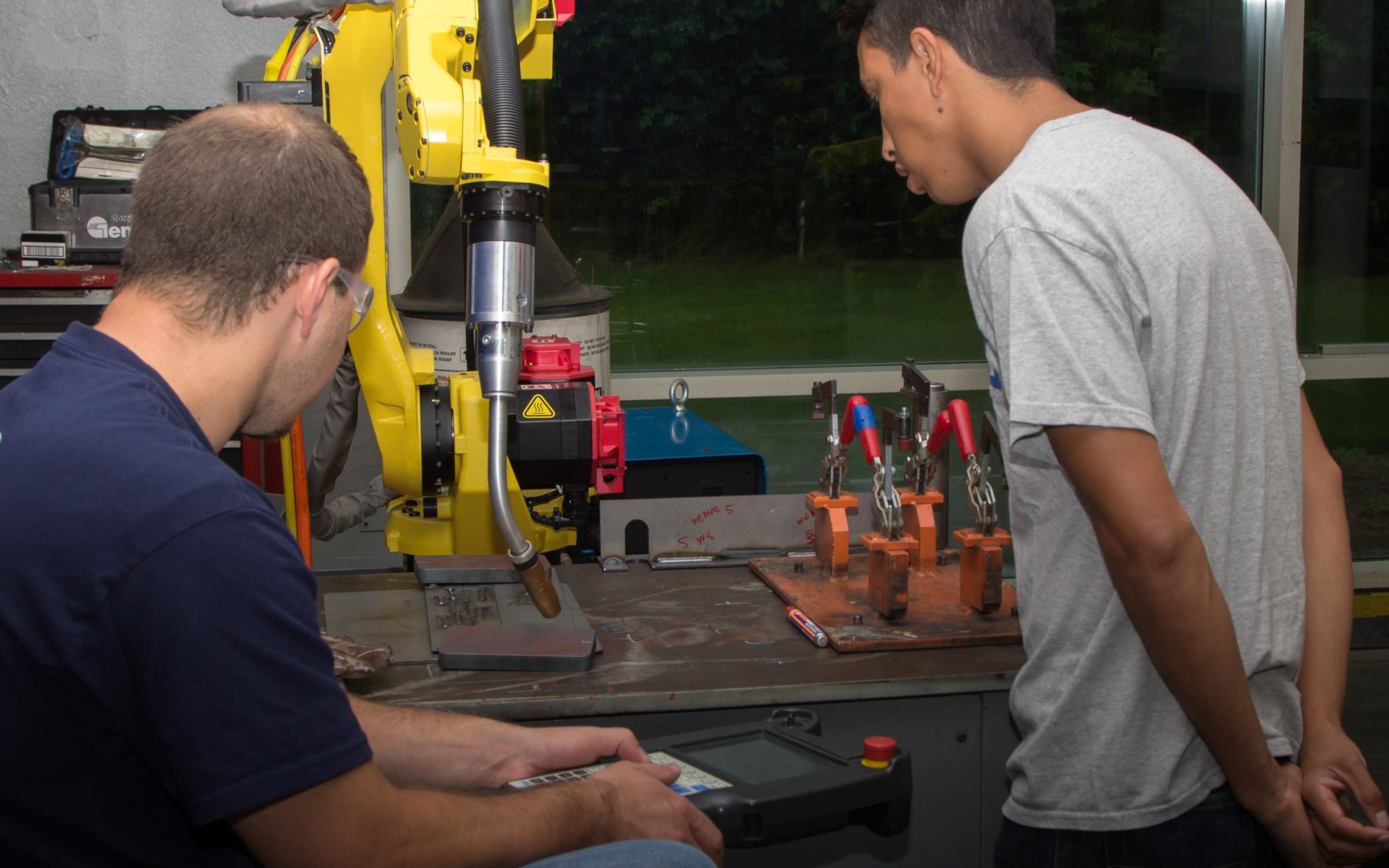

In today’s fast-evolving manufacturing landscape, the integration of robotic automation has become a game-changer for businesses looking to increase efficiency and reduce costs. However, with this advancement comes a critical need for properly trained robot operators who can ensure systems run smoothly and safely.

Robot operator training is not just a formality—it's a crucial investment in your workforce. Trained operators are better equipped to handle the complexities of modern robotics, from programming and maintenance to troubleshooting and system optimization. As technology continues to advance, ongoing education ensures that your team stays ahead of the curve.

The Benefits of Robot Operator Training

One of the most significant advantages of proper robot training is increased productivity. When operators are well-trained, they can quickly adapt to new systems, reducing the time it takes to get back up to speed after installation or upgrades. This minimizes downtime and helps maintain consistent output levels.

Safety is another major benefit. Robotics can be dangerous if not handled correctly, and training ensures that operators understand how to operate machines safely, follow protocols, and respond to emergencies. This not only protects workers but also reduces the risk of costly accidents and production halts.

Moreover, trained operators can significantly improve the return on investment (ROI) of your robotic systems. They can maximize machine uptime, optimize performance, and even identify opportunities for process improvements. In short, well-trained staff are key to getting the most out of your automation investments.

What to Look for in a Robot Training Program

Not all training programs are created equal. To get the most value, look for programs that offer hands-on experience. A good program should balance theory with practical application—ideally around 20% lecture and 80% hands-on work with actual robotic systems.

Another important factor is the quality of instruction. The trainers should have real-world experience across different types of robots and programming languages. They should also be able to tailor the curriculum to meet the specific needs of your team, ensuring that what’s taught is directly applicable to your operations.

Finally, consider the support offered after the training. Some programs provide follow-up resources, online materials, or even mentorship opportunities, which can help reinforce learning and address any challenges that arise post-training.

Robot training isn’t just about keeping up with technology—it’s about empowering your team to perform at their best. With the right program, you can build a skilled, confident, and efficient workforce that drives long-term success.

To learn more about effective robot training solutions, explore Genesis Systems Group’s comprehensive courses designed to help operators master the latest robotic technologies.

Posted in UncategorizedFour- Side Milling Angle Sanding Machine

Four- Side Milling Angle Sander,4 Sides Wood Edge Sanding Machine,Angle Edge Banding Machine,Four-Side Milling Equipment

Foshan Sandwell Machinery Co.,ltd , https://www.sandwellsand.com