Virtual Solutions Center: How Does Robot Simulation Help Robot Integration?

Virtual Solutions Center: How Does Robot Simulation Help in Robot Integration?

Robot simulation has been around for decades, but it wasn’t always the go-to solution for automation. In the early days, when robots were rare and extremely expensive, simulation was a common tool used by research institutions to test ideas and concepts before building physical systems.

As the 90s rolled in, robot prices dropped significantly, and companies began favoring real-world testing over virtual simulations. This shift led to a decline in the use of simulation tools for some time. However, with the rapid growth of computing power and the increasing complexity of robotic systems, the private sector has started to embrace simulation once again.

This trend is reshaping how robots are integrated into manufacturing and industrial environments. But before diving deeper into its impact, let’s explore how virtual solutions centers actually work.

What Are Virtual Solutions Centers and How Do They Function?

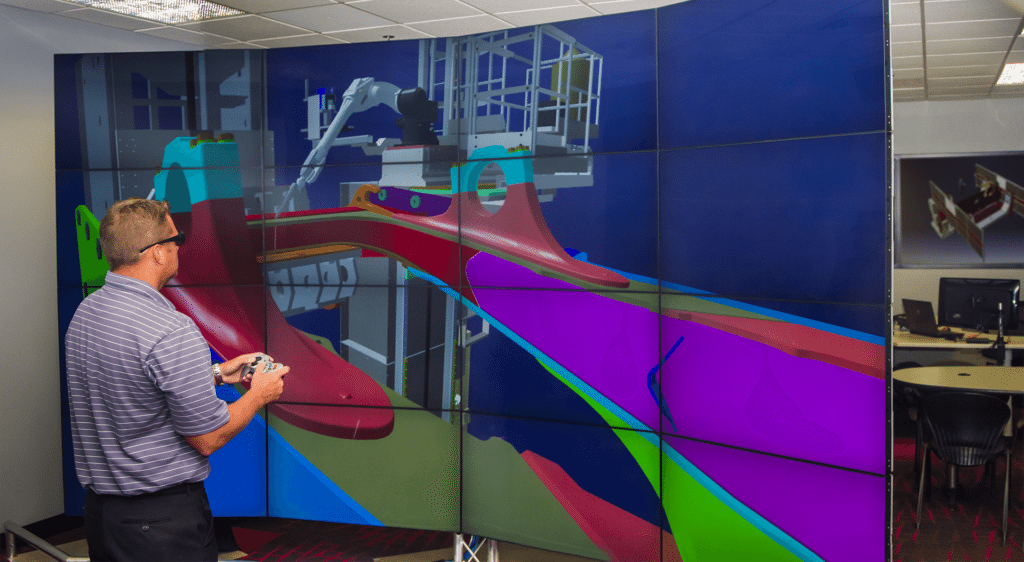

Virtual Solutions Centers (VSCs) are part of the services offered by robotic system integrators. These centers aim to create a full digital replica of a robotic system and its surrounding environment, including all process variables. This allows teams to demonstrate proof of concept without the need for physical prototypes.

VSCs closely mimic real-world applications, and often, the programming developed during the simulation can be directly transferred to the actual robot. This makes the transition from simulation to real-world deployment much smoother and more efficient.

Why Are Virtual Solutions Centers Essential?

VSCs play a crucial role in robotic integration for several reasons. First, they provide a safe and cost-effective way to test designs before any hardware is built. This helps identify potential design flaws early on, ensuring that the final product meets productivity expectations.

Additionally, simulations allow integrators to experiment with new technologies and optimize system performance in a controlled virtual environment. This not only improves efficiency but also reduces the risk associated with implementing complex robotic systems.

With the growing interest in automation, VSCs help lower the barriers to investment by reducing costs and minimizing downtime. As a result, they are becoming an essential tool for both manufacturers and integrators looking to stay competitive in the evolving robotics industry.

To learn more about how robot simulations work and see real-world applications, check out Genesis’ Virtual Solutions Center and discover how it's shaping the future of robotic automation.

Posted in Robotic WeldingPharmaceutical And Food Ultra-fine Grinding Mill

jet milling machine,air jet machine,jet milling machine for medicine,GMP Standard Pulverizer

Sichuan Shichuang Micro Nano Technology Co.,Ltd , https://www.scwnpowder.com

Very well explained the importance of virtual solutions for robot simulations. It also helped kids to understand the world of robotics at the beginning level. Thanks for sharing useful information.