Virtual Solutions Center: How Does Robot Simulation Help Robot Integration?

Virtual Solutions Center: How Does Robot Simulation Aid in Robot Integration?

Robot simulation has been around for decades, but it wasn't always the go-to solution for automation. In the early days, before robots were widely used and were extremely costly, simulation was a common tool among research groups to test ideas without the need for physical hardware.

By the 1990s, as robot prices dropped and became more accessible, many researchers shifted their focus from virtual models to real-world testing. This led to a decline in the popularity of simulations. However, with the rapid development of computing power and software capabilities in recent years, the private sector has once again turned to robot simulation for its numerous benefits.

This trend marks a significant shift in robotic automation. It not only improves efficiency but also reduces costs and risks associated with physical implementation. In this article, we’ll explore how Virtual Solutions Centers play a crucial role in modern robotics integration and why they are becoming an essential part of the process.

What Are Virtual Solutions Centers and How Do They Function?

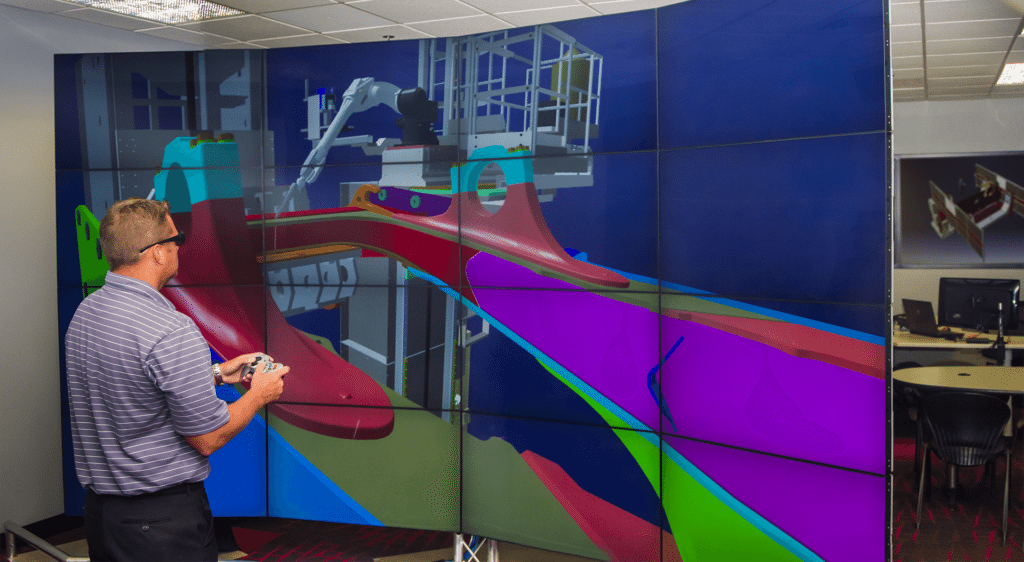

Virtual Solutions Centers (VSCs) are advanced tools used by robotic system integrators to create highly accurate digital replicas of real-world environments and robotic systems. These centers simulate everything from the robot’s movement to the surrounding production line, allowing engineers to test and refine processes before any physical installation takes place.

By using these virtual models, integrators can program and optimize the robot's behavior in a safe, controlled setting. Once the simulation is complete, the code can be directly transferred to the actual robot, significantly reducing setup time and ensuring smooth operation from day one.

Why Are Virtual Solutions Centers Important?

Virtual Solutions Centers are vital for several reasons. First, they allow for a proof of concept to be tested before any hardware is built, helping identify potential design flaws and ensuring that the final product meets performance expectations.

They also enable integrators to experiment with new technologies and complex applications in a risk-free environment. This not only enhances system efficiency but also encourages innovation within the robotics industry. Moreover, simulations help reduce the financial barriers to automation, making it more accessible for businesses of all sizes.

The growing adoption of Virtual Solutions Centers by robotics companies reflects a broader shift toward smarter, more efficient automation solutions. As technology continues to evolve, these virtual tools will play an even greater role in shaping the future of industrial robotics.

If you're interested in learning more about robot simulation and want to see real-world examples, take a closer look at Genesis’ Virtual Solutions Center.

Posted in Robotic WeldingUltrafine Powder Mill,Impact Type Ultrafine Pulverizer,Mechanical Grinder For Powders,Impact Mill Hammer Mill

Sichuan Shichuang Micro Nano Technology Co.,Ltd , https://www.scwnpowder.com

Very well explained the importance of virtual solutions for robot simulations. It also helped kids to understand the world of robotics at the beginning level. Thanks for sharing useful information.