The Importance of Proper Robot Operator Training

The Importance of Proper Robot Operator Training

Introducing robotic automation into any facility brings with it the need for skilled and well-trained operators. Without proper training, even the most advanced robotic systems can underperform or lead to costly errors. Robot operator training is not just a formality—it’s a critical component of ensuring long-term productivity and efficiency.

There are numerous robot training programs available today, and many integrators offer tailored courses. Choosing the right program can make a big difference in how effectively your team operates the robots. Well-trained operators are more confident, efficient, and better equipped to handle complex tasks, which ultimately leads to better results for your business.

The Benefits of Robot Operator Training

One of the main advantages of robot training is increased productivity. When operators are trained properly, they can quickly adapt to new systems and reduce the time it takes to get up to speed. This minimizes downtime and ensures that production runs smoothly from day one.

Safety is another major benefit. Robot training ensures that operators understand the risks involved and know how to operate machines safely. This not only protects employees but also reduces the likelihood of accidents that could disrupt operations or lead to expensive repairs.

Additionally, trained operators can help maximize your return on investment. With the right skills, they can optimize system performance, troubleshoot issues, and maintain high levels of uptime. In an industry where every minute counts, this can be a game-changer.

What to Look for in a Robot Training Program

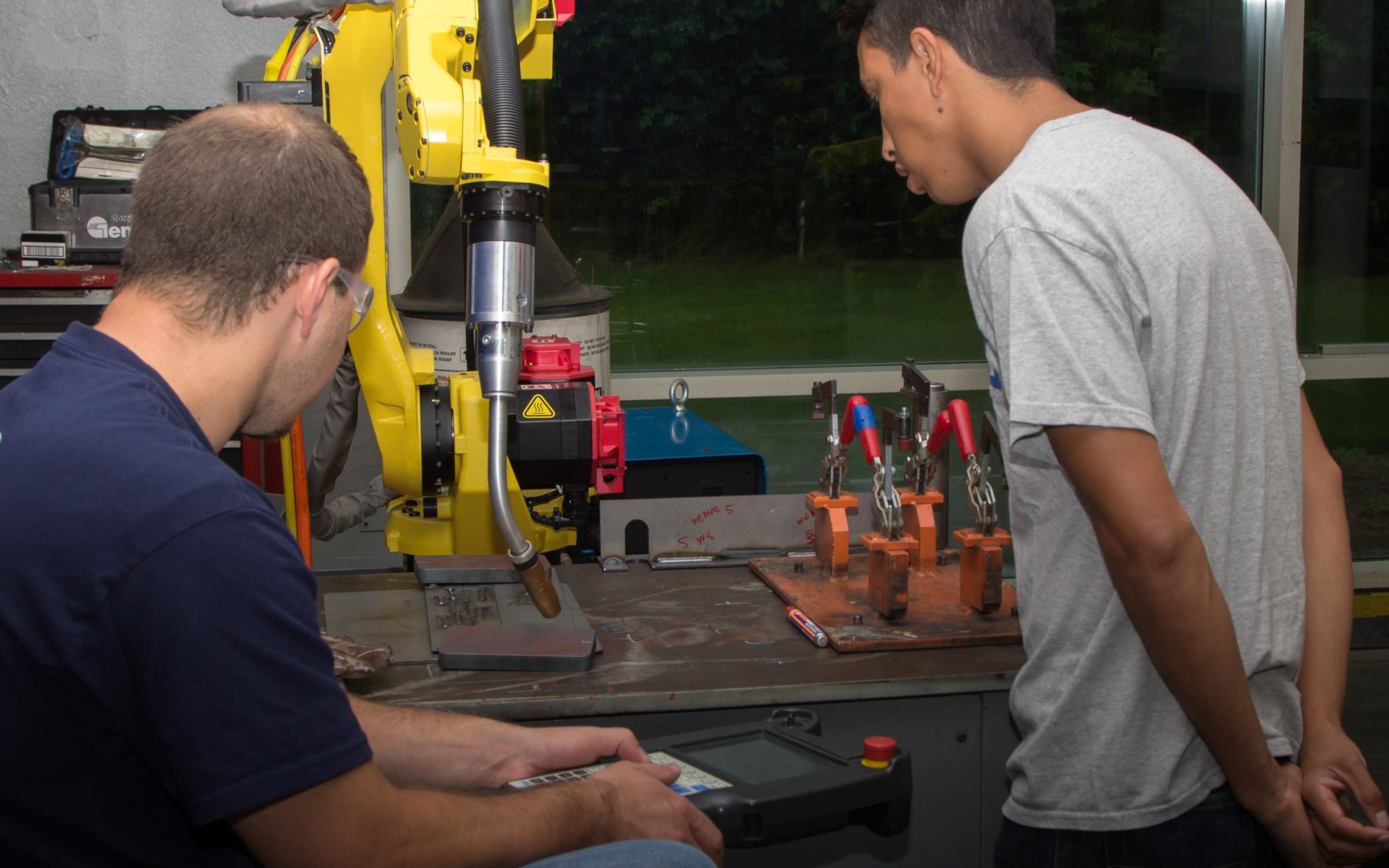

When selecting a robot training program, there are several key factors to consider. First, look for programs that emphasize hands-on learning. The best training involves direct interaction with real robotic systems rather than just theory. A good balance is around 20% lecture and 80% practical work with actual equipment.

Another important factor is the experience of the instructors. The trainers should have real-world expertise and a deep understanding of different robotic platforms. They should be able to adapt their teaching methods to suit the needs of each participant, making the learning process more effective and engaging.

Finally, ensure the program covers the latest technologies and programming techniques. Robotics is a fast-evolving field, and operators must stay updated to keep up with advancements. A quality training program will provide ongoing support and resources to help operators continue learning beyond the classroom.

In today's competitive manufacturing environment, investing in robot operator training is not just smart—it's essential. It helps build a skilled workforce, improves operational efficiency, and supports long-term growth. Whether you're implementing new systems or upgrading existing ones, the right training can make all the difference.

If you want to explore top-tier robot training options, check out Genesis Systems Group’s comprehensive and hands-on courses designed to prepare operators for the future of automation.

Posted in UncategorizedUV primer cabinet door sanding,Plastic uptake door panel sanding,MDF plate sanding and polishing,Multifunctional sanding machine,UV primer office furniture sanding

Foshan Sandwell Machinery Co.,ltd , https://www.sandwellsand.com