Understanding Working Load Limits - The Key to Safe Lifting and Towing

Have you ever wondered how much weight a lifting sling can handle, or how much cargo your forklift can safely lift? The answer lies in a key concept known as Working Load Limit (WLL). It’s not just a technical term—it’s the cornerstone of safe and successful lifting and towing operations!

What is Working Load Limit (WLL)?

Imagine you’re lifting a heavy box. You wouldn’t want the straps to snap halfway through, right? That’s where the Working Load Limit (WLL) comes in. Think of it as a built-in safety feature for your lifting and towing equipment. WLL specifies the maximum safe weight your equipment can handle under normal operating conditions.

Consider it similar to the weight limit on a bridge, which indicates the maximum safe weight for vehicles. By understanding and adhering to the working load limit, you can ensure your lifting and towing jobs are done safely and efficiently, avoiding accidents and protecting yourself and others.

Don’t Overload—Respect Your Equipment’s Limits

The Working Load Limit (WLL) is your equipment’s way of saying, “Hey, this is the most weight I can handle comfortably and safely!†It’s not just a random number; it takes into account factors like the equipment’s material, design, and built-in safety margin. Exceeding the WLL is like overloading a car—it can lead to breakdowns, injuries, or even equipment failure.

By respecting your equipment’s working load limit, you’re ensuring a smooth and safe operation. Remember, lifting and towing are physically demanding tasks, so treat your equipment with care and follow its recommended weight limit.

Why is WLL Important?

The Working Load Limit (WLL) isn’t just another technical specification—it’s a critical factor for ensuring safety and success in your lifting and towing operations. Here’s why understanding WLL is so important:

Preventing Accidents and Injuries

Lifting and towing heavy objects come with inherent risks. Exceeding the working load limit can have serious consequences. Imagine a strap snapping under excessive weight—it could cause the load to come crashing down, potentially injuring yourself or others nearby. WLL acts as a safeguard, preventing equipment failure and keeping you and those around you safe.

By following the working load limit, you can minimize the risk of accidents and injuries, creating a safer work environment for everyone involved.

Choosing the Right Equipment for the Job

Not all lifting and towing tasks are created equal! Some jobs require handling hefty objects, while others involve lighter loads. Understanding WLL empowers you to select the perfect equipment for the job.

Imagine you need to tow a car. By knowing the car’s weight and checking the working load limit of different tow straps, you can choose a strap with a capacity that safely exceeds the car’s weight. This ensures the strap won’t break during the towing process, keeping you and the vehicle secure.

By following the working load limit, you can avoid the risk of using inadequate equipment for the job. This not only prevents potential accidents but also protects your equipment from unnecessary strain and damage. It’s a win-win for safety and equipment longevity!

WLL vs. Breaking Strength: Understanding the Difference

You might come across another term—Breaking Strength—when reading about lifting and towing equipment. While they’re related, they’re not the same thing. Here’s how to tell them apart:

WLL - The Safe Working Limit

Think of Working Load Limit (WLL) as the green zone for your equipment. It’s the recommended safe weight limit you should adhere to during everyday lifting and towing operations. It factors in a built-in safety margin, ensuring your equipment can handle the load comfortably without risk of failure.

Breaking Strength - The Absolute Maximum

Breaking Strength, on the other hand, is like the absolute limit. It represents the maximum weight a piece of equipment can theoretically withstand before breaking. It’s determined through special tests that push the equipment to its very limits.

Important Note: While it’s tempting to think you can push your equipment to its Breaking Strength, it’s crucial to stay within the WLL. Exceeding the working load limit can permanently damage your equipment, reduce its lifespan, and increase the risk of accidents. Remember, working load limit is your safe zone for everyday use!

Safety Factor - Understanding the Built-in Buffer

The concept of Safety Factor (SF) is important when understanding the working load limit. It serves as a built-in safety margin for your lifting and towing equipment. It’s calculated by dividing the Minimum Breaking Strength (MBS) of the equipment by the Working Load Limit (WLL).

Here’s the formula: Safety Factor (SF) = MBS / WLL

In simpler terms, MBS represents the maximum weight a piece of equipment can withstand before breaking. The working load limit, on the other hand, is the safe working load you should adhere to during operations. The safety factor essentially indicates the buffer built into the equipment’s capacity.

A higher safety factor signifies a greater difference between the safe working load and the breaking point. For instance, a safety factor of 5:1 means the equipment’s MBS is five times greater than its working load limit. Common safety factors for lifting slings can range from 5:1 to 7:1, depending on the sling material and application.

By understanding the safety factor, you gain valuable insight into the equipment’s inherent level of conservatism. It reinforces the importance of staying within the working load limit and avoiding overloading, which could compromise the safety buffer and increase the risk of accidents.

How to Use Working Load Limit Information

Knowing the importance of WLL is great, but how do you actually use this information in practice? Here are some helpful tips:

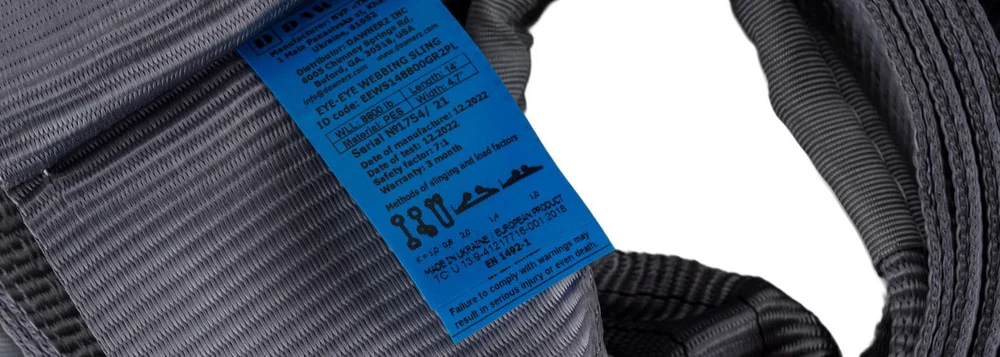

Reading Equipment Labels

The good news is, finding the working load limit for your equipment is usually quite straightforward. Most lifting and towing equipment will have a label that clearly displays the working load limit alongside other important information like model number and serial number.

Look for the WLL rating, often marked as "WLL" or "Working Load Limit."

Pro Tip: Don’t rely on memory! Always double-check the working load limit on the equipment label before each use. This ensures you’re using the most up-to-date information and considering any changes in the equipment’s condition.

Considering Additional Factors

While the Working Load Limit is a crucial factor, it’s not the only thing to consider for safe lifting and towing. Here are some additional elements that can influence safe operation:

Load Angle: The angle at which you lift or tow a load can impact the overall weight your equipment can handle. For instance, lifting a load straight up is generally safer than lifting at an angle.

Equipment Condition: Regularly inspect your equipment for any signs of wear and tear or damage. A damaged strap or sling might have a reduced WLL, so it’s important to use equipment in good working order.

Following Proper Lifting Techniques: For safe sling operations, use a spreader bar when lifting unbalanced loads, and ensure proper sling angles to avoid exceeding the WLL.

By considering these factors along with the working load limit, you can make informed decisions and create a safer environment for lifting and towing tasks.

Safety Tips for Lifting and Towing

Now that you understand WLL and its importance, here are some key safety tips to remember during lifting and towing operations:

Never Exceed the Working Load Limit – It’s Not a Suggestion!

This might seem obvious, but it’s worth emphasizing: Never exceed the Working Load Limit of your equipment. The WLL is there for a reason—it’s the safe weight limit designed to prevent equipment failure and potential accidents. Trying to lift or tow more weight than your equipment is rated for is not just risky, it can be dangerous.

Remember, exceeding the Working Load Limit can lead to:

- Equipment damage: Straps or slings could snap, and other equipment components could experience undue stress.

- Accidents and injuries: A broken strap or overloaded equipment could cause the load to fall, potentially injuring yourself or others.

Always stay within the WLL for safe and successful lifting and towing!

Inspect Your Equipment Regularly

Just like you wouldn’t drive a car with worn-out tires, you shouldn’t use damaged lifting and towing equipment. Make it a habit to inspect your equipment regularly before each use. Look for signs of wear and tear, cuts, fraying, or any other damage that could compromise the equipment’s strength.

If you notice any damage, don’t use the equipment! Replace it or have it professionally repaired to ensure safety during your lifting and towing tasks.

Use Proper Lifting and Towing Techniques

Safe lifting and towing with tow straps and web lifting slings requires proper techniques.

Here are some key things to remember:

Lifting Slings

Choose the right sling type

Select slings with the appropriate capacity (WLL) and material for the object being lifted. Consider factors like weight, shape, and lifting points. Inspect your slings before each use: Look for cuts, fraying, or any signs of damage. Never use damaged slings.

Use proper sling angles

Maintain recommended sling angles to avoid derating the WLL (reducing the safe load limit). Consult the manufacturer’s instructions for specific sling angles. Employ spreader bars for unbalanced loads: Spreader bars help distribute the weight evenly and prevent sling damage when lifting unbalanced objects.